Posted on 22nd January 2021

by Jacqui Vear

If you are a marketeer, it probably feels like the goal posts are constantly moving when it comes to your budgets, strategy and the motivations for your customer base! One buying motive that you need to keep a keen eye on is sustainability. Its key to the trust, authenticity and community focus that buyers are increasingly demanding from the brands that they choose to support. Let’s look at the sustainable printing process:

Paper is one of the few truly sustainable products, as wood is a natural and renewable material.

Print media is strong when it comes to sustainability. It also has one of the highest recycling rates of any material, currently 72% across Europe. In contrast, the Global E-Waste Monitor report confirmed that 53.6 million tonnes of e-waste were thrown away in 2019, with only 17% recycled. (Source: www.twosides.info)

Here are a few prompts as you progress your sustainable print project, from design to delivery on doormats;

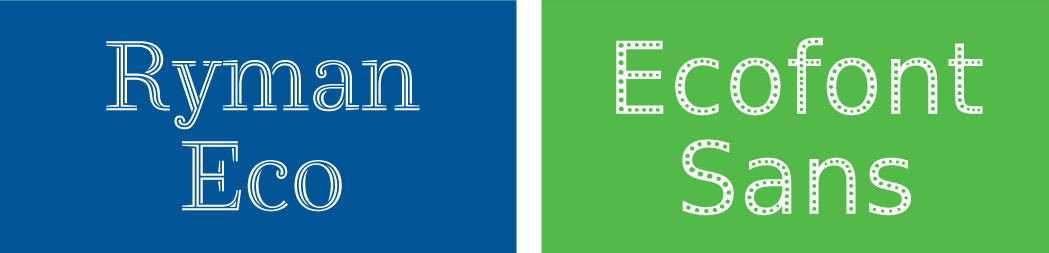

1. Use an eco font – The weight, size and kerning (the gap between each letter) of a font impacts on ink use, the speed of production and how many words you can fit on a page, obviously impacting on paper use. Lighter-weight, narrow fonts, with simple no-frills styling will have less of a draw on resources and even make the process of recycling easier. Widely available fonts that are lighter on ink include Century Gothic and Garamond, or there are specifically designed eco fonts such as Ryman Eco and Ecofont Sans.

2. Minimise waste by optimising the finished size of your printed item – At the design stage of your project you’ll be thinking about the dimensions of your printed item or its page count. Knowing what printing method is going to be used will inform a decision about an efficient approach, which minimises paper waste.

3. Select a sustainable paper stock – Across all weights of paper, a key consideration is whether paper stock is certified to the Forest Stewardship Council® (FSC®) or the Programme for the Endorsement of Forest Certification™ (PEFC™). For our team this is the default choice, but its always worth adding this point to your checklist. Both schemes ensure that the raw material of wood fibre is sourced from sustainable forests, where land is responsibly managed, natural habitats of plants and animals are conserved, and the rights of forestry workers and local communities are respected. Recycled paper is a further option, yet it is important that you select paper with the highest level of ‘post-consumer waste paper’ aim for 100%. If you want to make a sustainable stock choice a feature within your project you could consider FSC® certified Gmund Bio Cycle papers, which are made from plant fibres and are compostable. Up to 50% of these papers comes from fibres that include wheat straw, grass, cotton and cannabis! The stock colour and texture reflect its composition, yet that is all part of it creating a point of difference.

4. Use an environmental message or imprint within your design – When you’ve proactively thought about the certification of your paper stock and how your printed item can be disposed of when it’s no longer required, share those pointers with your audience. Include a statement, icon or logo to reinforce your choices and hopefully encourage others to follow your lead in their own marketing projects.

5. Production efficiency – Sustainable printing processes should minimise the use of chemicals, through inks or the substances, such as sprays and sealants, that could be used to dry printed sheets. Using modern, energy efficient printing presses will also reduce the carbon footprint of this stage of your project.

6. Choose print finishes carefully – Print finishes or embellishments are the finishing touches you put to your project specifications. Finishes such as embossing, debossing and die-cutting apply nothing new to your product, so do not compromise its ability to be recycled. Lamination has traditionally been the process where a thin layer of plastic film is applied to printed paper or card. It prevents cracking on the spine of books and generally keeps your marketing pristine! Yet a plastic free laminate is now available. It’s made predominantly from cellulose, which is a type of organic plant material that’s biodegradable. It provides the same aesthetic appearance as traditional lamination but can be recycled in a normal re-pulping system that paper goes through.

7. If you’re mailing your sustainable print project, think about any packaging – ‘Naked mailing’ is a phrase that means your printed item is posted without any additional packaging, such as postcards and increasingly catalogues. If you’re posting items that need to be collated or protect, new starch based mailing wraps are eco-friendly. They’re made from the starch in potatoes and can be placed in home composting or food waste bins. When potato starch polywrap is in contact with micro-organisms, it will fully compost in just 10 days. If it does go to landfill, it will biodegrade and leave no visible litter trail.

8. Only produce what you need – Choosing a print volume is a balancing act! You quickly gain economies of scale in print and it can be tempting to order more. To minimise waste, think about whether your item can be designed in a generic way such that it will be relevant beyond the short-term and potentially held in stock. Perhaps you can progress orders for similar items at the same time, coordinating projects across different branches?

9. Make every contact count – For mailing projects, minimise waste and maximise return on investment by ensuring your campaign is targeted and your data is clean, which is a requirement under data protection legislation too. Processes will involve postal address correction, de-duplication, deceased and gone away suppression. For marketing mail, you should also screen your contacts against the Mail Preference Service, a list of individuals who have specifically opted out of receiving marketing information in the post.

10. Carbon neutral printing – You can mitigate the CO2 emissions created by the production and distribution of your print project through a Carbon Capture Scheme. The contribution will be relevant to each impact and you can receive regular certificates to show how this has led to carbon capture in new woodland.

So, there you have ten steps and lots of points to consider! Yet this work is all in the interests of boosting the positive impact of your sustainable printing projects and you can delegate away to our team. Helping you win business and do business is our mission. We would like to help you improve the sustainability of your purchasing too, an approach that we call The Green Dot. For your peace of mind, the processes behind it are accredited to ISO 14001:2015.